How can astronauts build a lunar base if traditional building materials are too heavy to load into a rocket?

In 1975, three years after the final Apollo Moon landing, Space: 1999 first aired on British television. It began with a nuclear explosion wrenching the Moon, and an international lunar colony of over 300 people, out of its orbit and into an unknown journey into space.

The TV series obviously made an impression on a young Elon Musk because, when the SpaceX founder revealed their plans for a lunar colony in August 2017, he called it Moonbase Alpha after the lunar base in Space: 1999. “Cheesy show,” Musk tweeted, “but I loved it.”

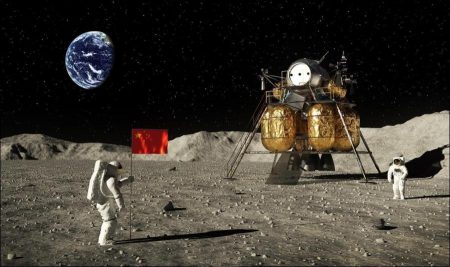

SpaceX is not alone is wanting to get humans back on the Moon. The Chinese space agency CNSA (China National Space Administration) has announced the next stages of its successful Chang’e lunar exploration missions – shortly after Chang’e 4 became the first spacecraft to make a soft landing on the far side of the Moon.

Chang’e 5 and 6 will be sample return missions while Chang’e 7 will survey the South Pole, a region of specific interest for human habitation because it contains water ice. “We hope that Chang’e 8 will help test some technologies and do some exploring,” deputy head of the CNSA Wu Yanhua said in January, “for the building of a joint lunar base shared by multiple countries.”

China is not alone in this ambition. Across the globe, 50 years after the Moon landings, the practicalities of a moonbase are taking shape. The irony is that, while only the United States of America has left footprints on the Moon, the Americans are now having to play catch up. It didn’t unveil plans for a permanent moonbase until August 2018. Nasa’s primary focus until then had been Mars. The European Space Agency (Esa) was already one step ahead.

Moon village

Esa announced plans for a permanent lunar base in 2016. Pioneered by its new director-general, Jan Woerner, his vision for a ‘Moon village’ would contain a diverse population of people – from scientists to artists – and both public and private organisations. This could be for astronomical research, tourism or geological prospecting for minerals in short supply on Earth.

He was definitely ahead of the curve. Ariel Ekblaw, founder of the MIT Media Lab’s Space Exploration Initiative, also wants to “democratise space” and, to this end, has brought together multi-disciplinary research groups ranging from robotics and synthetic neurobiology to architecture, art, space and design.

Not everyone used to think this way but Esa science advisor, Aidan Cowley, also welcomed Woerner’s idea as he was one of the first to work on lunar technologies at Esa’s European Astronaut Centre in Cologne, Germany. “At first every one looked at me as if I had a second head,” he laughs, “so for me it’s been very satisfying to see the uptick in interest and this focus on the Moon. Jan read the tea leaves.”

Unlike Nasa, which has an exclusion policy for working with China on spaceflight, Esa also collaborates with CNSA. “Last year we had Esa astronauts Matthais Maurer and Samantha Cristoforretti participating with Chinese colleagues on sea rescue and survival,” says Cowley.

Nasa aims to land astronauts on the lunar surface by 2030 and is planning a lunar orbiting platform called the Gateway. Private companies are heading to the Moon too. Blue Origin, for instance, is partnering with OHB and MT Aerospace on its Blue Moon cargo ship for a lunar landing. But whichever organisation gets there first, the key priority will be survival. The longest time humans have lived on the Moon so far is just three days. For longer stays, it’s not the most welcoming of destinations.

Destination Moon

The Moon has temperatures ranging from 127 to -173 C (260 to -343F). Then there’s radiation and the low gravity, one-sixth that of the Earth’s. A lunar day is also around 29 Earth days, which means two weeks of daylight followed by two weeks of darkness – an issue for solar power. Any new technologies for a lunar outpost must therefore work under these conditions.

With this endeavour in mind, several organisations – including Blue Origin, Airbus Defence and Space and Esa – recently helped set up a non-profit organisation called The Moon Race. This global competition is to encourage companies to develop technologies in the areas of manufacturing, energy production, resources (filling a bottle with lunar water) and biology (to sustain the first lunar greenhouse) and will officially launch in October 2019 at the International Astronautical Congress.

“We will issue guidelines and rules within the next month,” says Germany-based Airbus space engineer and Moon Race co-founder, Pierre-Alexis Joumel. “The competition will last five years because the ambition of The Moon Race is to bring the best team’s idea up to the Moon’s surface.”

The technology prototypes selected for testing under lunar conditions will hitch a ride onboard a lunar mission. “The missions we are targeting are mostly from space agencies. One is planned for 2024-25.”

Building a home

Despite the imaginative concept art of early moonbases, the reality is more basic. And grey. Travelling to the Moon is expensive. The heavier the payload, the more fuel required and the higher the cost. Building a living space out of the Moon’s available resources makes sense. There’s the potential of using lava tubes, tunnels formed during the Moon’s volcanic past, as shelters with access to frozen water ice beneath the surface. But a more immediate plan is to build a habitat using lunar regolith, the fine dark balsaltic grey sand that is similar to volcanic sand on Earth.

Professor Matthias Sperl from the University of Cologne works with the German Space Agency, DLR, using volcanic powder to make bricks. The regolith simulant is held together using a process called sintering, where concentrated sunlight or lasers bond the material together. He used 3D printers to construct different shaped bricks to see which worked best. “What we can build with current techniques and shapes is interlocking building elements,” said Sperl. “We’re not building Lego but we have interlocking bricks.”

These bricks would “build something like an igloo, then it’s strong against additional pressure from above.” The pressure would be from a metre layer or so of loose regolith, to offer a natural protection against radiation as there is no wind on the Moon to blow it away.

“You need to bring a square metre or more big lens to capture the solar light to allow 3D sintering and printing of lunar dust,” said Sperl. “Then you need an astronaut or mostly likely a robot to bring those pieces together to bring together a settlement.”

But building just one structure would be a slow process. “It takes roughly five hours to make a brick,” said Sperl, “and you need 10,000 bricks for an igloo. It will take months.”

This time could be reduced if more lenses are in operation and construction is performed robotically, but it is a feasible plan. “Lunar regolith can build something as strong as concrete,” said Sperl. “Current technologies only give you one-fifth that strength, around that of gypsum, so further investment is needed to get to the ultimate strengths.”

The next stage is sizing up. Fortunately construction will start later this year on a large Esa lunar facility that can help prepare for both technologies and living on the Moon.

Survival

Since evidence of water ice was detected at the Moon’s poles, and finally confirmed by Nasa in August last year, any moonbase is likely to be situated at these locations. It’s no coincidence that Chang’e 4’s Yutu 2 rover is currently collecting information in the South Pole’s Aitken Basin. The water ice can be found on the surface in permanently shadowed areas of craters and underground.

Oxygen within the lunar regolith itself could also be extracted for breathing. The most likely source is ilmenite (FeTiO3) which, when combined with hydrogen at temperatures of around 1,000C (1,832F), produces water vapour, which then needs to be separated to produce hydrogen and oxygen.

To begin with, astronauts will need to bring food and drink supplies. Chang’e 4 caused excitement by germinating and sprouting a seed, but producing sustainable food in space is not a new idea. It began in 1982, when Soviet cosmonauts grew Arabidopsis thaliana, a member of the mustard family, on the Salyut 7 space station. In 2010 the University of Arizona developed a prototype ‘lunar greenhouse’ – a hydroponic system using a 5.5 metre membrane covered tube, water-cooled sodium vapour lamps and “envelopes” to hold the seeds using carbon dioxide from astronauts’ breath and urine to provide water. Fibre-optic cables supplied sunlight.

Energy

New energy technologies will be key to living on the Moon. Fuel cells on Earth require a chemical reaction between hydrogen and oxygen (often from the air) to produce electricity, with water as a byproduct. While there’s no atmosphere on the Moon, the ingredients are there.

“You could split the water we have on the Moon and during the night recombine it to produce electricity,” says Cowley, who is developing these new technologies. “During the day we’ve got a lot of solar power, probably excess to split the water into hydrogen and oxygen, so it’s a unique tool we could use on the Moon to sustain a long duration mission.”

There is also the potential of thermal energy storage using a process similar to heat pumps. “On the Moon we don’t have convection as there’s no wind so the heat from the Sun stays in the regolith,” says Cowley. “We could use a lens or mirror to focus sunlight onto the ground and use that resource to keep a base warm or to generate electricity.”

Once these technologies are perfected and tested to ensure they will work under lunar conditions, astronauts will be able to build a moonbase. It will be sooner than you think.

Views: 385